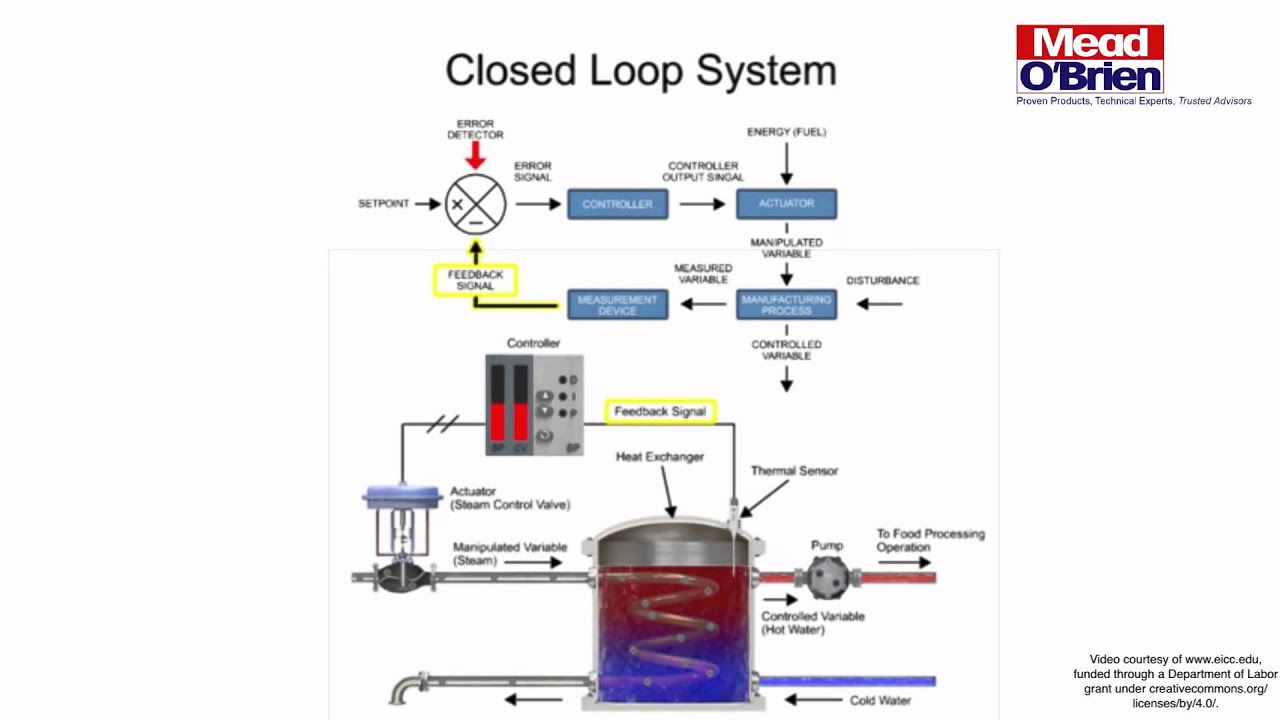

Closed Loop Hydronic System

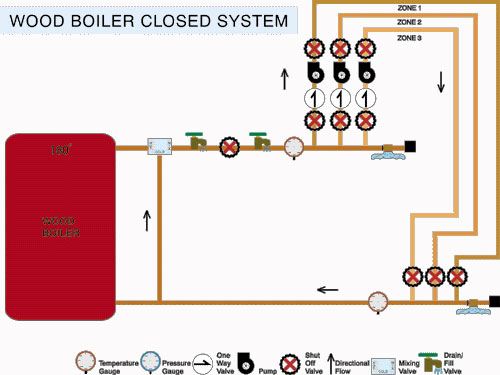

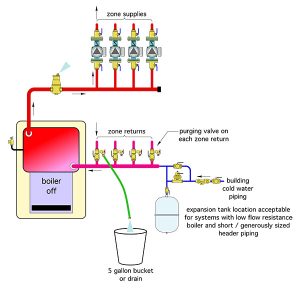

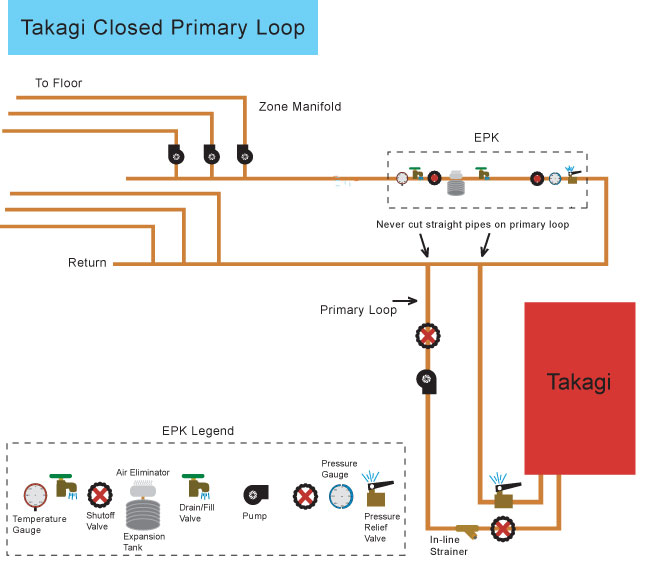

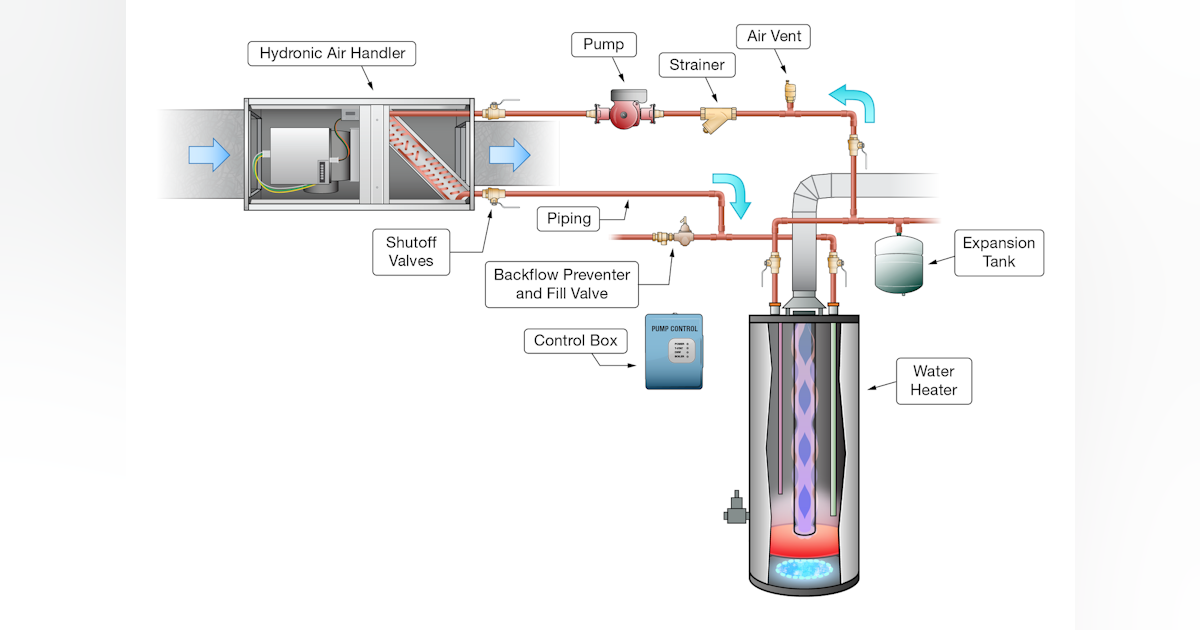

Closed loop hydronic system. There is no connection whatsoever to the domestic water supply. The variations in the factors controlling corrosion. Hot water runs through the tubes to heat your house from the ground up.

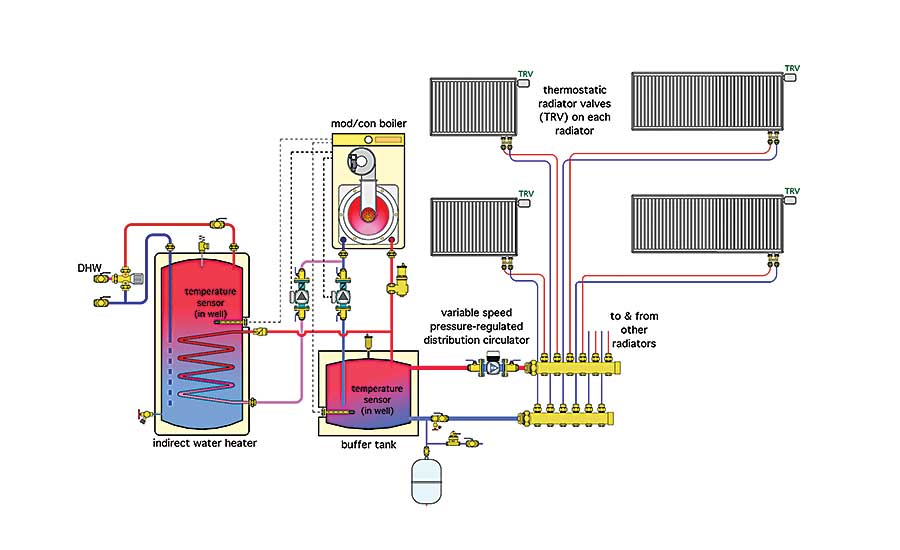

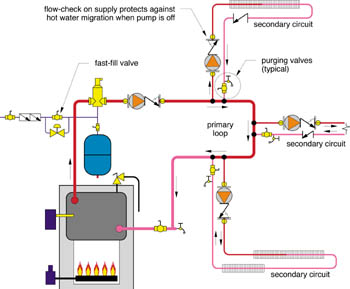

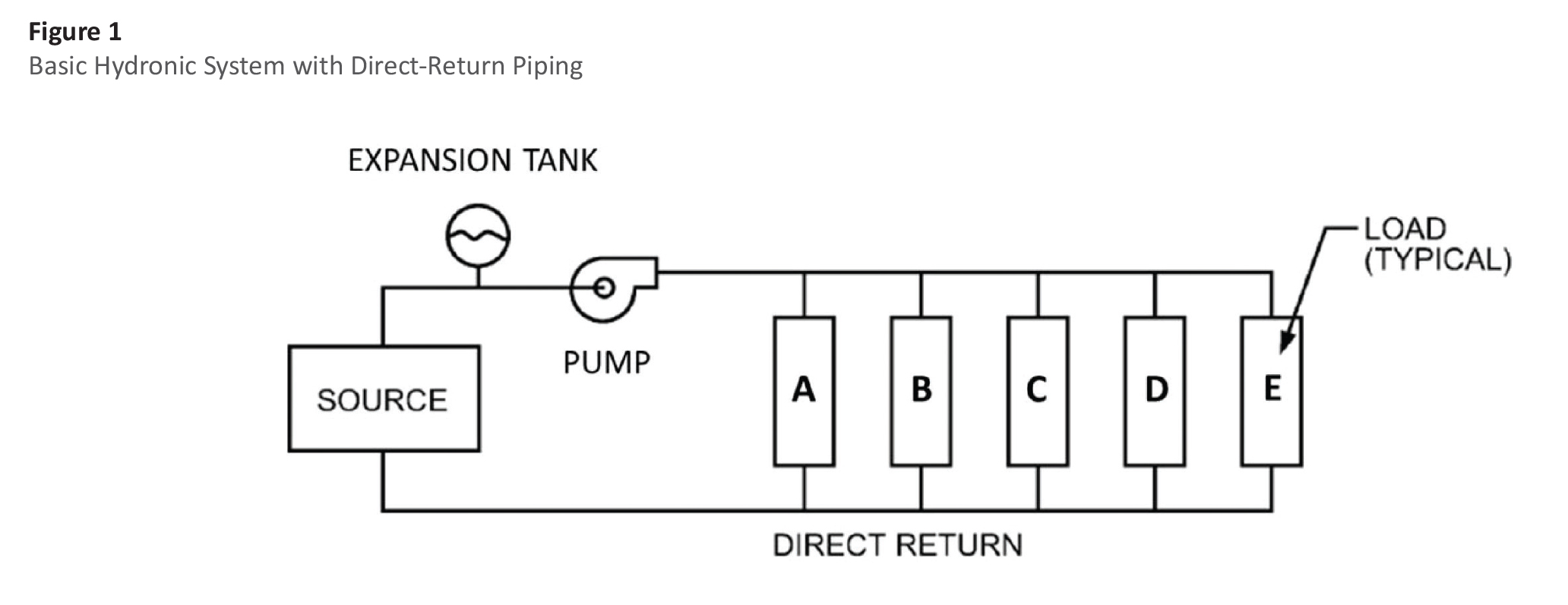

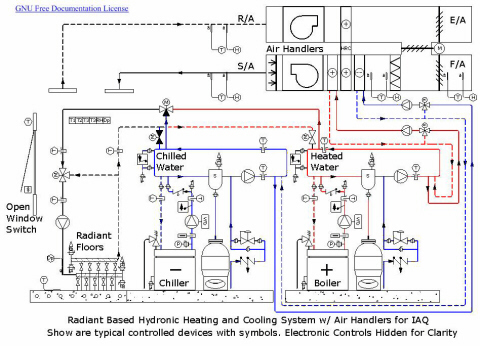

Most plumbing and heating contractors recognize the closed loop system as a common. 21- BRPDR 90 design Branch Water Flow Is Variable Chiller Sees Variable. It must first accurately monitor the system for changes in load dynamics.

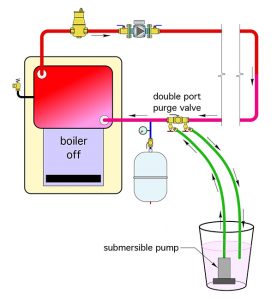

What is a closed loop boiler system. A loop flushing valve andor relief valves can be built into a closed loop motor. Rey Molybdate and Non-Molybdate Options for Closed Systems Page 4 of 27.

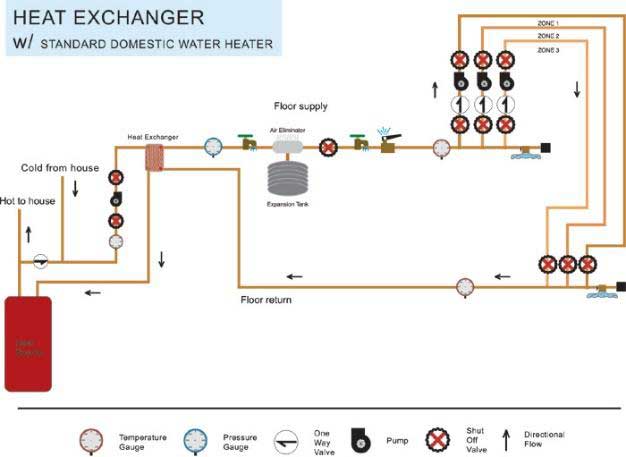

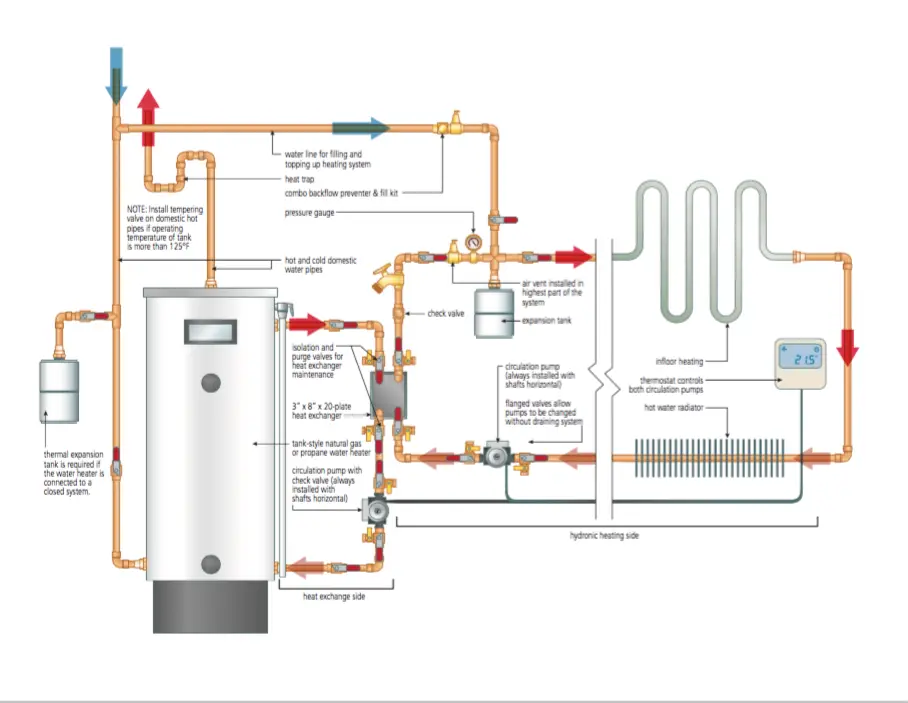

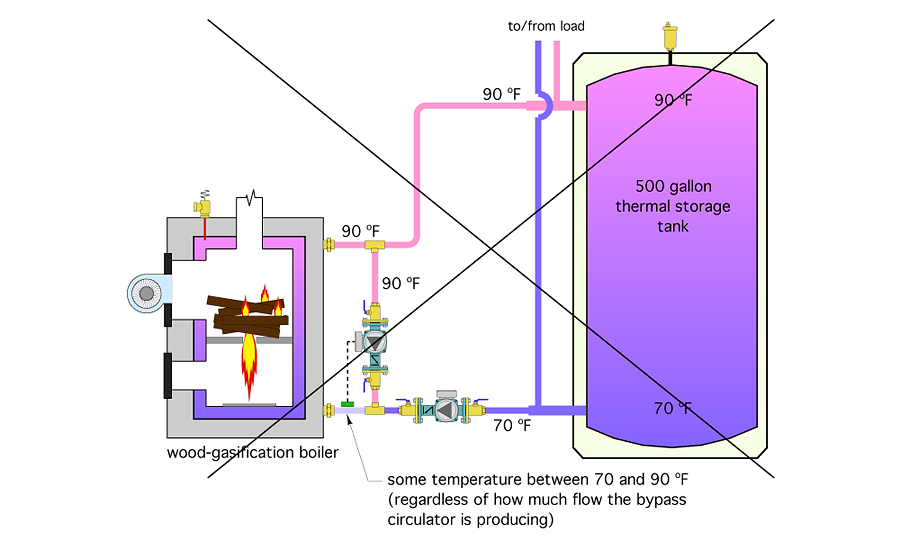

By adding ethylene glycol to the water to create a 60 solution the freezing point plummets to minus 60 degrees Fahrenheit. Each system is efficient in its own way and it is entirely up to the homeowner which system fits their home and lifestyle. The main advantage to this system lies in the fact that being closed anti-freeze instead of water can be used as the heat transfer medium.

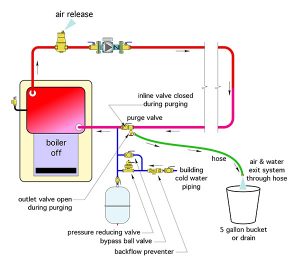

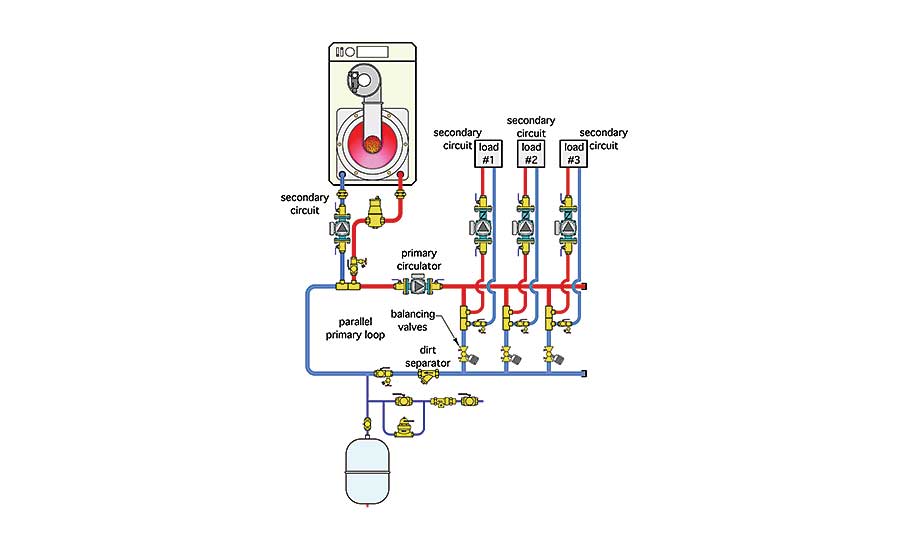

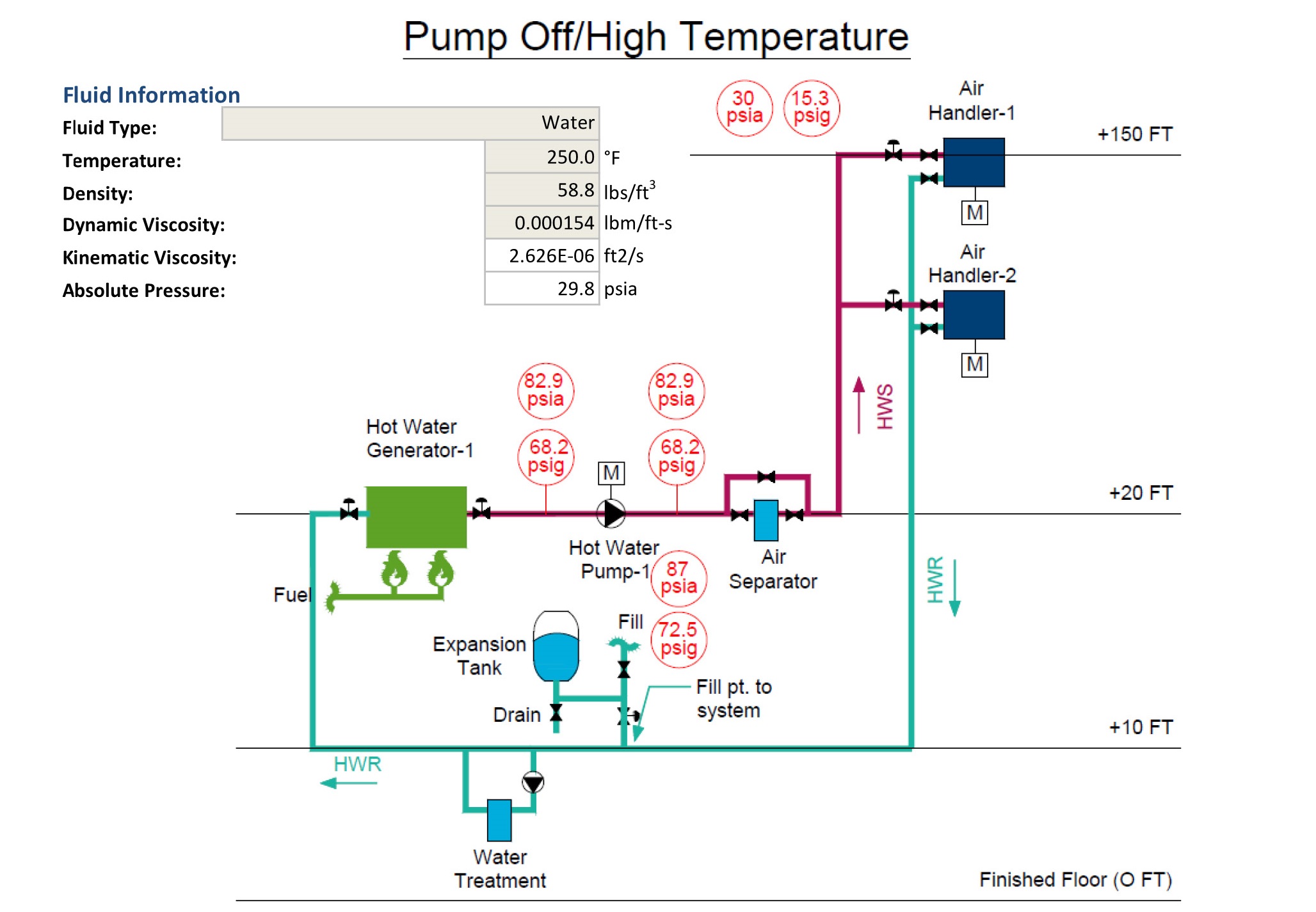

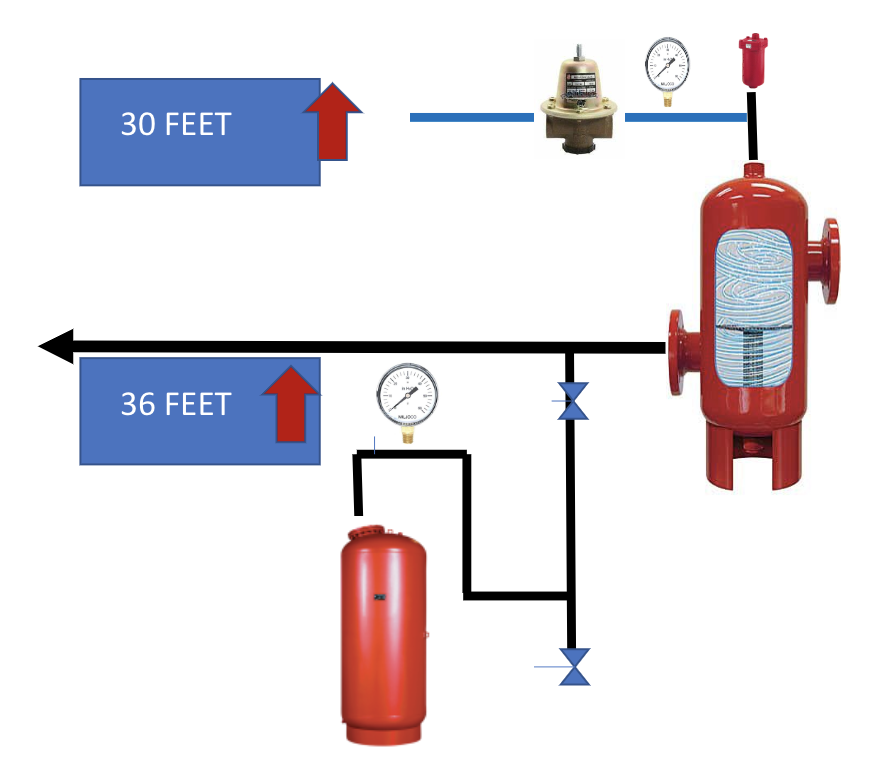

Air Elimination And Closed-Loop Hydronics. Friction of the water rubbing against the pipe as it flows through the system. 1 PSI of pressure drop 231 feet of head Does height of the building influence head loss.

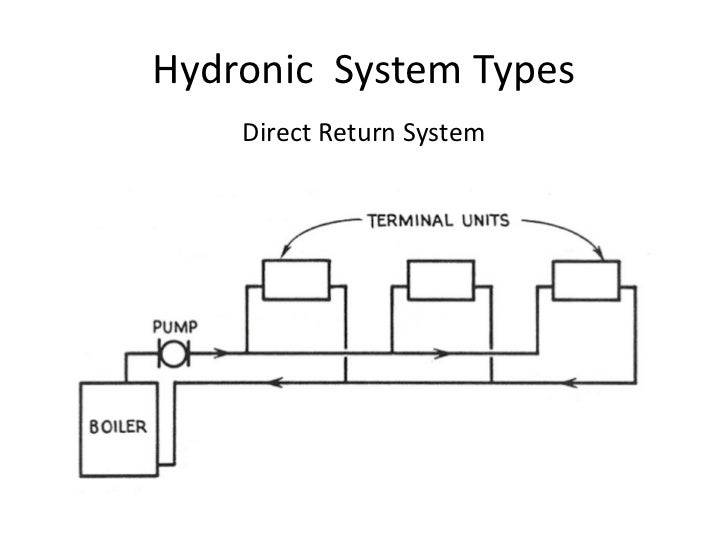

Closed system water treatment chemicals are used to protect chill water and hot water recirculation systems from corrosion and scale formation along with biocidal control of microorganisms. Closed Loop Circulating System Two Pipe Direct Return Definition. The closed loop means that there is no wasted water in a hydronic heating system.

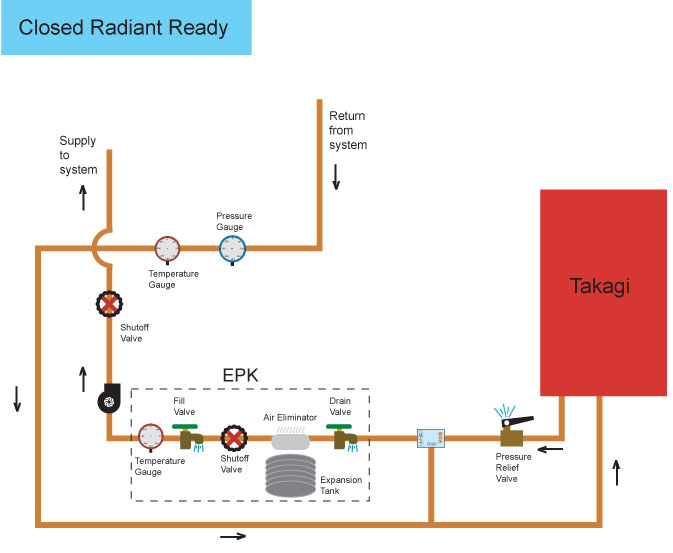

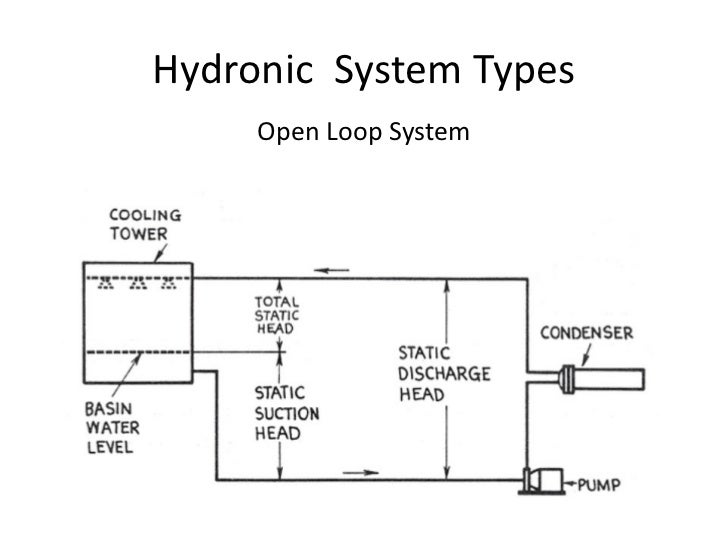

The difference in circulator head for open vs. If the homeowner feels the need to separate the heating and potable water aspects of the home and decides to install a secondary unit for radiant heating purposes then that is a closed loop system.

The make-up water not only dilutes the corrosion inhibitor and reduces its effectiveness but also adds oxygen which can promote corrosion on many surfaces.

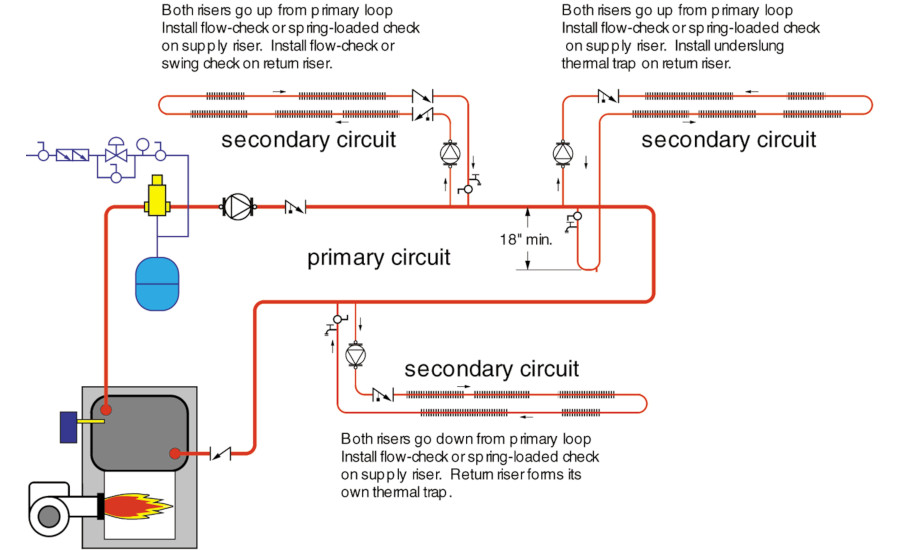

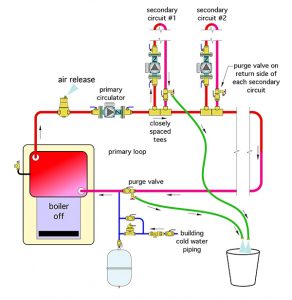

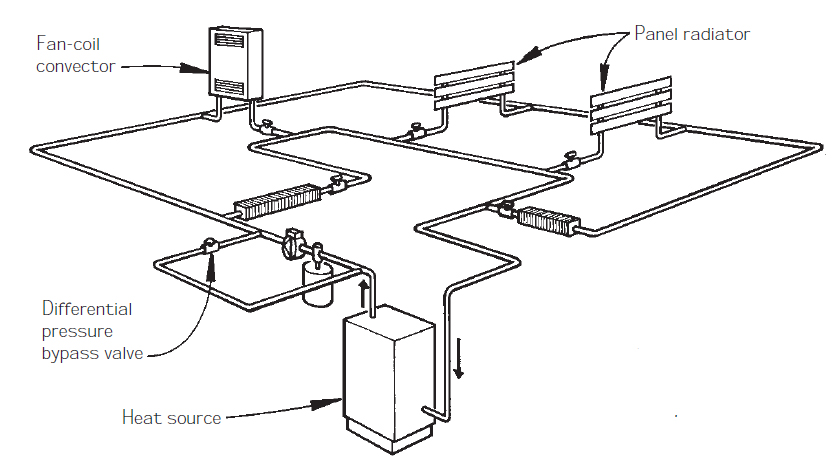

Zone Loop Building Loop Injection Series Pumping System Advantages zLower Operating Cost Reduced pump horsepower by separating zones with different loads Disadvantages zIncreased Number of Pumps and First Cost zOperation of Pumps Affects Flow in Other Circuits zPumps are not decoupled zIncreased complexity of balancing IHL-1 100F 110F 30000 BTUH. Just because a hydronic system appears to be completely filled often times there is more in the system than what we think. For open loop system a directional control valve. They generally operate bi-directionally and must have some special features to be appropriate. Closed Loop Circulating System Two Pipe Direct Return Definition. What is a closed loop boiler system. The make-up water not only dilutes the corrosion inhibitor and reduces its effectiveness but also adds oxygen which can promote corrosion on many surfaces. Each system is efficient in its own way and it is entirely up to the homeowner which system fits their home and lifestyle. Closed system water treatment chemicals are used to protect chill water and hot water recirculation systems from corrosion and scale formation along with biocidal control of microorganisms.

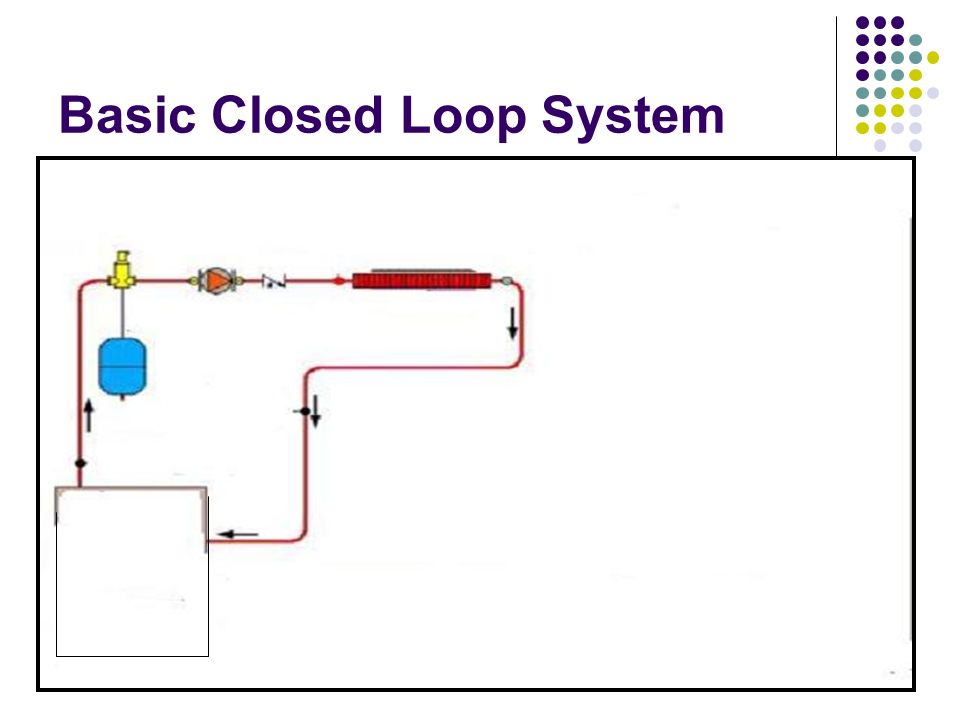

A loop flushing valve andor relief valves can be built into a closed loop motor. Nearly all closed loop hydronic heating and cooling systems are supposed to be filled with water or a mixture of water and antifreeze. Closed recirculating systems or closed hydronic loops utilize a water-based solution to transfer heat. The closed loop means that there is no wasted water in a hydronic heating system. The difference in circulator head for open vs. Closed Loop Circulating System Two Pipe Direct Return Definition. The closed loop means that there is no wasted water in a hydronic heating system.

Posting Komentar untuk "Closed Loop Hydronic System"