Paul Bos Heat Treatment

Paul bos heat treatment. If you are just getting into knife making or are an experienced veteran this video will probably help you out one way. He said he also has seen the cryogenic process produce higher performance in guitar strings womens nylon stockings gun barrels and engine parts. Paul Bos a nationally known heat-treat authority has been heat-treating since 1956.

Before his retirement from Buck Knives in 2010 he served 70 of Americas custom knife makers as well as overseeing all of the heat-treating in Buck Knives factory where he was able to consult with Bucks engineers. All wood is stabilized in house by Chapman Made. TWISTED SISAL MERCH - THANKS TO MISHEARDKNIFEREVIEWS.

Paul Bos a nationally known heat-treat authority has been heat-treating since 1956. Oil or plate or air quench to below 125F. This is because of the heat treatment and hardening process designed by Paul Bos of Buck Knives back in the 1960s.

Its chemistry promotes the formation and even distribution of vanadium carbides which are harder and more effective at cutting than chromium carbides. A little lengthy but a lot of info. The company passed to Srsens wife Gloria after his death with daily operations now being handled by the Srsens daughter Kim and grandson Brian Zayicek.

Bos one of Americas foremost authorities on heat treating steel has developed the recipes used for many of Bucks steels. S30V also needed to be easily heat treated with common knife heat treating equipment which was why Paul Bos was consulted. Twice at 400-1200F for 2 hours minimum each time.

Micarta G10 domestic and exotic wood. Loved this build for Nathan Khol. His heat treating system has proven to be the best in the business Bos proprietary process is an industry secret but its not.

1300 degrees is where you are aiming for. Ramp to 1900-2000F and hold at temperature for 30-60 minutes.

It was founded in 1968 by Henry J Srsen with one heat treating furnace.

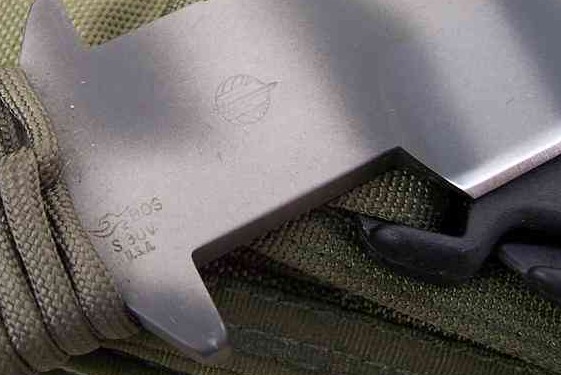

Heat to 1400 and equalize. These vanadium carbides give the steel a very refined grain further improving the sharpness and toughness. Loved this build for Nathan Khol. Heat to 1400 and equalize. If the blade turns bright red you have gone too far. S30V also needed to be easily heat treated with common knife heat treating equipment which was why Paul Bos was consulted. Paul Bos a nationally known heat-treat authority has been heat-treating since 1956. It is 8 12 long and has a 4 14 single edge and 2 double edge. Before his retirement from Buck Knives in 2010 he served 70 of Americas custom knife makers as well as overseeing all of the heat-treating in Buck Knives factory where he was able to consult with Bucks engineers.

Despite some difficulties with a consistent heat. Bos one of Americas foremost authorities on heat treating steel has developed the recipes used for many of Bucks steels. Each knife blade undergoes Bucks heat treat process along with a quality performance test. Bucks proprietary heat treating process was pioneered by industry legend Paul Bos. When parts of the blade start to turn dull red you are at about 1000 degrees. Micarta G10 domestic and exotic wood. Despite some difficulties with a consistent heat.

Posting Komentar untuk "Paul Bos Heat Treatment"